CET computer control

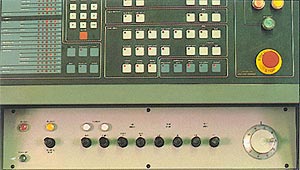

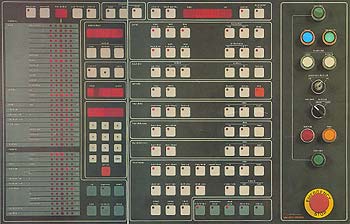

All machine functions are programmable through the unique microprocessor based CET control which has a pressure sensitive Mylar type keyboard, proof against the ingress of dirt and coolant.

The keypads, which give a tactile response, are labelled in plain language and provide a means for manual data input.

A function prompt LED display gives visibility to the line being programmed plus two lines before and two lines after. This is particularly useful when programming complex overlapping operations.

Programming is based upon a logical sequential system requiring a minimum of operator training as there are no codes to learn.

Programming

- select the function by pressing the appropriate key,

- enter the required value on the numeric keypad ie; travel; feedrate; turret position; speed etc, (alternatively turret strokes can be set using the teach and learn handwheel)

- value is displayed for verification prior to entry,

- press data input key,

- repeat for other functions in sequence required.

Overriding corrections can be made at any time to all functions and the control will accept either inch or metric; but only one system may be used within a single program.

Incorrect program sequencing or omissions are signalled by an error display on the keyboard to prompt remedial action. All slides can be operated simultaneously with full overlapping of operations independent of each other.

Canned cycles for turret slide forward and reverse; woodpecker drilling; tapping; feed bar to stop and traverse slide multi-pass are provided as an aid to speedy and accurate programming.

The ability to optimise feedrates during machining is invaluable for developing shorter cycle times.

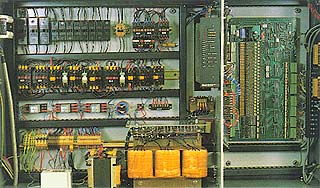

The system has electronic feed back monitoring by a closed loop servo system providing full electronic monitoring of the turret slide for precise feed and accurate positional control.

A batch/cycle counter with completion shut down is fitted as an aid to efficient unmanned operation.

A diagnostic system is provided to assist in tracing electrical faults.

Storage for 300 lines (approx. 25 part programs) is provided within the control's memory.