Tooling

Part-off Toolholder Assembly Sprint E

Part No. 561-04

The assembly consists of cranked toolholder 11223 insert type toolholder 11424 and box of 10 carbide inserts 11425.

Alternative inserts are available with right hand rake 11426.

Part-off Toolholder Assembly Sprint S

Part No. 561-05

The assembly consists of toolholder 11624, insert type toolholder 11625 and box of 10 carbide inserts 11429.

Part-off and Chamfer Toolholder Assembly - MicroSprint 32

Part No. 561-06

The assembly consists of toolholder 31007, part-off insert type toolholder 11428, chamfer insert type toolholder 31008, box of 10 carbide part-off inserts 11429 and box of 10 carbide chamfer inserts 31010.

Single Part-off Toolholder Assembly - MicroSprint 50

Part No. 561-08

The assembly consists of toolholder and three (3) clamp blocks only. Three (3) types of blade are available:

| Part No. | Description |

| 33108 | HSS blade (pack of 5) |

| 33109 | 4mm wide brazed carbide blade (pack of 5) |

| 33110 | 3mm wide brazed carbide blade (pack of 5 - suitable up to 15/8" dia. bar only). |

Single Part-off Toolholder Assembly - MicroSprint 26

Part No. 561-09

The assembly consists of toolholder 31011 and one part-off blade 31012.

| Part No. | Description |

| 31013 | Pack of 10 blades (sold separately) |

Spacer for Part-off Toolholder Assembly - MicroSprint 26

Part No. MA1-562-01

This spacer moves the part-off toolholders 561-09 and 561-10, 10mm away from the collet, enabling a lead chamfer to be formed behind the part-off face.

The assembly comprises spacer MA 06297 and 4 off socket head cap screws.

Single Part-off Toolholder Assembly - MicroSprint 26

Part No. 561-10

The assembly consists of Toolholder 31014, and one insert type blade holder 31015.

| Part No. | Description |

| 31016 | Pack of 10 inserts (sold separately). |

Vertical slide adjustable toolholder Assembly - MicroSprint 26

Part No. MA1-965-01

This Toolholder uses ½" square tools (not supplied)

Coolant Pipe for Turret Coolant Distribution Assembly - MicroSprint 50 and 26

Part No. MA1-992-01

The assembly consists of:

| Part No. | Description |

| 13145 | 1/8" nozzle |

| 13146 | ¼" bore hose (2 off) |

| 13147 | ¼" NPT connector |

| 36055711 | Adaptor ¼" BSP/8 mm |

| 36056102 | ¼" BSPT plug |

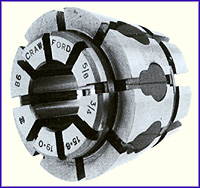

Collet sleeves and nosecaps - MicroSprint 32 and Sprint E

A separate collet sleeve and cap are required for each type of collet used on a machine, i.e. Dead Length Spring Collet or Multibore Collet.

| Part No. | Description |

| 11233 | Multibore Collet Sleeve |

| 11234 | Multibore Collet Cap |

| 11236 | Herbert No. 1 (2046) Spring, Collet Sleeve and Cap |

| 11237 | Brown and Sharpe (4812) Spring, Collet Sleeve and Cap |

| 11238 | Index 25 (2099) Spring, Collet Sleeve and Cap |

| 11239 | Traub A25 (8744) Spring, Collet Sleeve and Cap |

Note: Crawford Collet reference in brackets.

Collet sleeves and nosecaps - MicroSprint 26

A separate collet sleeve and cap are required for each type of collet used on a machine, i.e. Dead Length Spring Collet or Multibore Collet.

| Part No. | Description |

| ME02289 | Multibore Collet Sleeve |

| MA06009 | Multibore Collet Cap |

| 11295 | Herbert No. 1 (2046) Spring, Collet Sleeve and Cap |

| 11296 | Brown and Sharpe (4812) Spring, Collet Sleeve and Cap |

Note: Crawford Collet reference in brackets.

Collet sleeves and nosecaps - Sprint S and MicroSpritn 50

A separate collet sleeve and cap are required for each type of collet used on a machine, i.e. Dead Length Spring Collet or Multibore Collet.

| Part No. | Description |

| MS 04399 | Multibore Collet Cap |

| MS 04456 | Multibore Collet Sleeve |

| MS 04892 | Herbert 2D Collet Cap (2047) |

| MS 04893 | Herbert 2D Collet Sleeve (2047) |

Note: Crawford Collet reference in brackets.

Multibore Rear Support Stop

This is fitted into the Multibore Collet to support the rear of the Collet on second operation work. The domed head supports the rear of the collet and also has provision for an adjustable stop.

Fitting instructions are supplied.

| Part No. | For Use On |

| 11235 | Sprint E |

| 11325 | MicroSprint 32 |

| 11636 | Sprint S and MicroSprint 50 |

Sprint Collets for MicroSprint 26, 32 and Sprint E

The standard spring collets for the Sprint E, MicroSprint 26 and MicroSprint 32 are the Herbert No. 1 type (Ref: 2046). These are normally stocked in the following sizes:

Round - 1/32" to 1" in 1/32" steps (2mm to 26mm in 1mm steps)

Hexagon - 20 common sizes from 3/16" to 7/8" A/F. Metric sizes are not normally available.

Square - Not normally available.

Note: Each collet will only grip one size of bar, although a latitude of 0.005" (0.13mm) can usually be accommodated.

Multibore Collets

These collets are available for all current Emi-Mec machines. Each collet is adjustable over a range of 1/8" and therefore a small number of collets are required to cover the range of the machine in imperial and metric sizes.

See our Collets page for more details.

Second Operation Support Stop

This stop fits into the spindle bore of the machine and is suitable for most second operation work. The backstop is adjustable for a wide range of components, eliminating the need for individual stops for each job.

| Part No. | Description |

| 25151 | For use on MicroSprint 32 |

| MA1-962-01 | For use on MicroSprint 26 |

| MS1-962-01 | For use on MicroSprint 50 and Sprint S |

Micro-adjustable Knee Toolholder

Part No. 99885

Knee toolholder with micro-adjustment for turned diameter and has a 3/4" diameter bore which can be bushed for end machining, i.e. centre drill, etc.

Note: Bushes and tools are not supplied.

| Turning capacity | 0-0.87" dia x 1.62" long 0.87-1.5" dia x 1.0" long | |

| Tool size | 1/2" square | |

| Shank dia | 1.0" |

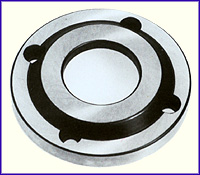

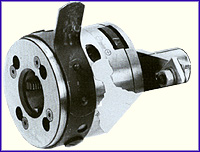

200mm Autoblock Pneumatic Chuck

Technical Data

| Chuck size | 200mm diameter x 78mm deep | |

| Capacity | Outside 12-225mm (0.47" to 8.86") diameter Inside 64-265mm (2.52" to 10.43") diameter | |

| Approximate weight | Chuck assembly: 32 kg (70.5 lbs), Chuck body: 18 kg (39.5 lbs) | |

| Maximum recommended Speed | 1900rpm |

| Part No. | Description |

| 460-12 | Three Jaw Chuck Assembly, complete with all fittings, guards and instructions for Sprint S. |

| 460-14 | Two Jaw Chuck Assembly, complete with all fittings, guards and instructions for Sprint S. |

| MS1-905-01 | Three Jaw Chuck Assembly for MicroSprint 50. |

| MS1-906-01 | Two Jaw Chuck Assembly for MicroSprint 50. |

| MS1-907-01 | Chuck Adaptor and Guard for MicroSprint 50. |

| MS1-908-01 | Air Chuck Valve Panel for MicroSprint 50. |

| 11290 | Steel Soft Jaw, for Two or Three Jaw Chuck. Please state number of jaws required as these are sold individually not as sets. |

| 11291 | Three Jaw Chuck Body. |

| 11292 | Draw Bar. |

| 11293 | Cylinder Adaptor. |

| 11294 | Air Cylinder. |

| 11299 | Two Jaw Chuck Body. |

Note: The chuck assembly (MS1-905-01 or MS1-906-01) does not include a valve control box (MS1-908-01) or a chuck adaptor and guard assembly (MS1-907-01). All three items are required when initially setting up to use the machine in the chucking mode.

100mm Evenlode Pneumatic Chuck

Technical Data

| Chuck size | 100mm diameter x 49.5mm deep | |||||

| Capacities (Min-Max) | Part No. Outside dia Inside dia |

11301 3-115 6-123 |

11302 3-92 6-99 |

11311 3-90 6-100 |

11312 3-90 6-100 | |

| Part No. | Description |

| 11300 | Three Jaw Chuck Assembly complete |

| 11301 | Set of Three Aluminium Jaws |

| 11302 | Set of Three Aluminium 'Pie' Jaws |

| 11310 | Two Jaw Chuck Assembly complete |

| 11311 | Set of Two Aluminium Jaws |

| 11312 | Set of Two Aluminium 'Pie' Jaws |

| MEl-740 | Three Jaw Chuck Assembly complete (MS 32) |

| MEl-741 | Two Jaw Chuck Assembly complete (MS 32) |

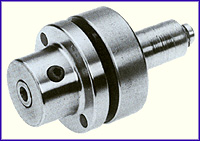

Revolving Bar Stop

Part No. 11200

The head of the bar stop is free to rotate when coming into contact with the stock bar. Thus, there is no need to stop the spindle when feeding bar and the possibility of damaging the bar end is greatly reduced.

| Diameter | 1.0" | |

| Length | 4.5" |

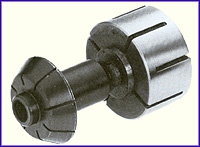

Combined Workcatcher and Revolving Bar Stop (Air Operated)

This item permits double utilisation of one turret station. Having a revolving head and a threaded shank, the stop affords the same benefits as 11200, but can also be adjusted for length. The workcatcher is pneumatically operated via the turret air distributor and may be programmed to release the machined component during the machines automatic cycle.

| Part No. | Catcher Depth | Component Length | Shank Diameter |

| 11201 | 1.56" | 3.87" (max.) | 1.0" |

| 11401 | 2.56" | 4.37" (max.) | 1.0" |

Knee Tool with Fixed Toolholder

Part No. 11209

This toolholder can be used for simple turning and chamfering operations. It has provision for blank bushing, which may be bored to accommodate a centre drill or similar tool. Thus it can be used to perform two cutting operations at one time.

Note: Bushes and tools are not supplied.

| Turning capacity | 0-0.87" dia x 1.62" long 0.87-1.5" dia x 1.0" long | |

| Tool size | 1/2" square | |

| Shank dia | 1.0" |

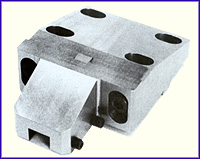

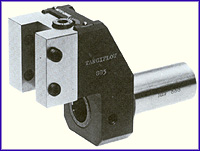

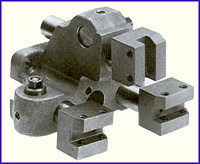

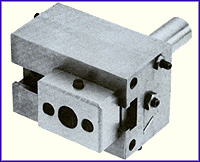

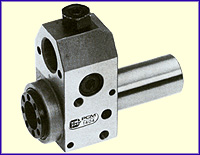

Turret Multi Toolholder

Part No. 11404

This toolholder can be used on the Sprint S, MicroSprint 50 and 26 machines. Drilling, turning, facing and chamfering operations can be carried out simultaneously. Three toolholders are provided but no cutting tools.

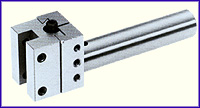

Adjustable Toolholder

Part No. 11405

For use with multi-tool holder and knee toolholders. The offset shank enables the toolholder to be used in an inverted position if required. The screw adjustment enables a range of diameters to be handled without disturbing the cutting tool.

| Shank dia | 1.0" | |

| Tool size | 1/2" square |

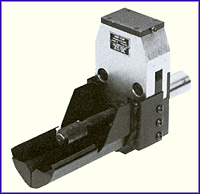

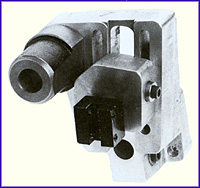

Adjustable Knee Toolholder

Part No. 11409

This toolholder can be used on the MicroSprint 50, 26 and Sprint S machines for turning, or turning and boring operations. The adjustable slide allows a wide range of diameters to be catered for within the capacity of the machine with the minimum of tool overhang. The toolholder can be steadied by means of the overhead steady bar (except MicroSprint 26). A steel toolholder is provided but no cutting tools.

Roller Steady Ending Toolholder

Part No. 11204

Ideal for Facing and Forming the end of turned bars. The roller steadies are adjustable for different diameters, and allows the work to run at normal turning speeds.

| Shank diameter | 1.0" | |

| Capacity | 0.28-1.25" diameter | |

| Tool size | 11/32" X 7/16" |

Knurling Tool with Fixed Holders

Part No. 11206

This tool is supplied with medium diamond knurls (19 TPI). Spare knurls are available from most tool stockists.

| Knurl size | 3/4" o/d x 1/4" bore x 1/4" | |

| Knurling capacity | 1.0" dia x 1.5" | |

| Shank diameter | 1.0" |

Auto-Retract Roller Box

On completion of cut, tool is retracted automatically from the work face, eliminating withdrawal marking.

Part No. 11203

| Shank diameter | 1.0" | |

| Capacity | 0.125"-0.5" x 6.0" long 0.5"-0.75" x 2.75" long |

Part No. 11343 Flange Mount

| Capacity | 0.25" - 2" dia x 7" long |

Note: 11343 fits MicroSprint 26, 50 and Sprint S. Cutting inserts are not supplied with these roller boxes.

Air Operated Roller Box

This box is similar to Part No. 11203, but flange mounted, and with air operated retract mechanism.

Part No. 11403

| Capacity | 0.19" - 1.25" diameter |

Part No. 11603

| Capacity | 0.44" - 1.62" diameter 1.62" - 2.0" x 6.5" long |

Note: Both boxes can be fitted to MicroSprint 50, 26 and Sprint S. Cutting inserts are not supplied with the roller box.

Cutting Inserts for Roller Boxes

Cutting inserts are stocked in ISO grade P25/35 which is suitable for general work on all classes of steel. Inserts are sold in packs of 10 only.

| Part No. | Description |

| 11403-504 | Carbide insert for 11203 and 11403 |

| 11603-510 | Carbide insert for 11603 |

| 11344 | Carbide insert for 11343 |

Boring and Recessing Tool Slide

Part No. 11208

Normally, this tool is used for cutting an internal undercut or recess. The spring loaded slide is actuated by a pusher mounted on the cross slide. This can be replaced by a template for short taper turning. The slide can be locked in any position to allow it to be used as a boring toolholder.

There is an adjustable stop to regulate the diameter produced. The stroke of the slide is 0.37" but the range of diameters can be increased by movement of the toolholder in the 'T' slot.

| Shank diameter | 1.0" | |

| Tool diameter | 0.5" |

Boring and Recessing Tool Slide

Part No. 11408

Details as for Part No. 11208, but with larger capacity for use on the MicroSprint 50, 26 and Sprint S machines.

| Shank diameter | 1.0" | |

| Slide stroke | 1.12" | |

| Tool diameter | 0.75" |

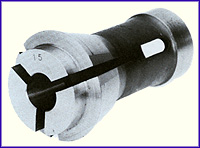

Centering and Facing Toolholder

Principally used for providing a true centre for drilling. The toolholder incorporates two blades for facing end of bar. Cutters may also be arranged for counterboring and chamfering.

| Part No. | Drill | Capacity | Shank |

| 11423 | 0.50" dia | 2.37" dia | 1.00" dia |

| 11614 | 0.87" dia | 3.00" dia | 1.50" dia |

Adjustable Toolholder

Part No. 11217

Ideal for holding small drills, reamers etc. The holder may be adjusted for alignment and then bolted firmly to the shank, or it may be allowed to float free.

| Shank diameter | 1.0" | |

| Capacity | 1.0" dia x 1.19" deep |

Floating Reamer Holder

The floating characteristics of this holder allow the reamer to follow its own path whilst cutting. Thus, allowance is made for slight discrepancies in concentricity.

| Part No. | Shank Diameter | Capacity |

| 11218 | 1.0" | No. 2 Morse |

| 11612 | 1.5" | No. 3 Morse |

Morse Taper Sleeve

A simple holder for mounting morse taper shank drills and reamers, etc., in the turret bore.

| Part No. | Shank Diameter | Morse Taper |

| 11219 | 1.0" | No. 1 |

| 11220 | 1.0" | No. 2 |

| 11605 | 1.5" | No. 2 |

| 11606 | 1.5" | No. 3 |

Split Adaptor Bush

Part No. 11616

For adapting 1.0" shank tools to fit toolholders or turret with 1.5" bores.

| Outside diameter | 1.5" | |

| Bore | 1.0" | |

| Overall length | 2.62" |

Key Drill Chuck

Self centering, for holding centre drills, small drills, etc. Chuck key included.

| Part No. | Capacity | Shank |

| 11216 | 0-0.5" dia | 1.0" dia |

| 11802 | 0.19-0.75" dia | No. 3 M.T |

Self-opening Coventry Diehead

A stationary diehead with pull-off trip action. These dieheads are suitable for most general threaded work. The chasers may be replaced very quickly with diehead remaining on the turret, if necessary. Cushioning movement between the diehead and the shank accommodates slight differences between turret feed and screw thread lead. These dieheads may be closed automatically with the diehead closers on the following page.

| Part No. | Diehead Type | A | B | C | D |

| 11213 | 12mm 'DS' | 2.56" | 1.89" | 1.0" | 2.50" |

| 11402 | 20mm 'DS' | 3.23" | 2.4" | 1.0" | 3.44" |

| 11602 | 11/4" 'CHS' | 4.19" | 3.81 " | 1.5" | 4.62" |

Air Operated Diehead Closer

This item is for use only with the self-opening dieheads. The closer is pneumatically operated via the turret air distributor, and may be programmed to close the diehead at any point in the machines automatic cycle.

Diehead Closer

| Part No. | Type | Shank |

| 11214 | 12mm 'DS' | 1.0" |

| 11407 | 20mm 'DS' | 1.0" |

| 11615 | 11/4" 'CHS' | 1.5" |

Diehead Used On

| Part No. | Type | Shank |

| 11213 | 12mm 'DS' | 1.0" |

| 11402 | 20mm 'DS' | 1.0" |

| 11602 | 11/4"'CHS' | 1.5" |

Tap Holder - Releasing Type

Part No. 11210

The holder is held stationary whilst tapping but releases, allowing the tap to rotate with the work, when the required depth is reached. When the lathe spindle is reversed, a clutch incorporated in the holder prevents the tap from rotating.

| Shank diameter | 1.0" | |

| Capacity | Min. not recommended for 3/16" (5mm) dia taps or below. Max. 5/8" dia shank taps. |

Note: Bushes required for each size of tap shank.

'PAFIX' Self-Feed Tap Head

The tap is held in a flexible collet, and driven from the squared end. Once engaged the tap feeds in automatically to a pre-set thread depth. The thread length is adjustable in 0.254mm increments. The positive clutch and automatic release ensures consistent thread lengths. Supplied with setting instructions.

Tapheads

| Part No. | Taphead | Approximate Tread Range | Maximum Thread Length |

| 11315 | GK 21 | 4-14mm dia | 22mm |

| 11319 | GK 41 | 8-27mm dia 22mm |

Sets of Collets and Drivers

| Part No. | Collet Capacity (Tap Shank Dia) | Used On | Drivers Sizes (Tap Shank Sq.) |

| 11316 | 4.0-12.0mm | GK 21 | 3.15-9.0mm |

| 11320 | 8.0-20.0mm | GK 41 | 6.3-16.0mm |

Note: A set of collets and drivers will be required in addition to the relevant tapping head.

Parting Off Toolholder for MicroSprint 32 and Sprint E

Part No. 11223

When fitted to the vertical slide this toolholder allows parting off close to the collet nosecap face.

The toolholder accepts a 1/2" square tool.

Turret Face Extension Toolholder

Bolted directly to the turret station face, this holder is used to extend a short bodied tool.

It is supplied with clamp cotter bolt and fixing bolts.

MicroSprint 32 and AutoSprint E

| Part No. | Description |

| 11221 | Overall length: 3.125", Bore: 1.0" dia, Material: Aluminium Alloy |

| 11222 | Overall length: 3.125", Bore: 1.0" dia, Material: Cast Iron |

MicroSprint 26, 50 and AutoSprint S

| Part No. | Description |

| 11411 | Overall length: 3.25", Bore: 1.0" dia, Material: Aluminium Alloy |

| 11412 | Overall length: 3.25", Bore: 1.5" dia, Material: Aluminium Alloy |

| 11415 | Overall length: 3.25", Bore: 1.0" dia, Material: Cast Iron |

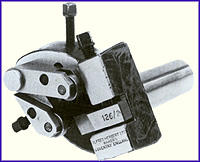

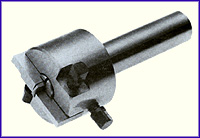

Multi-purpose Single Toolholder

Part No. 991404

This toolholder in conjunction with either the simple cutter holder or micro-adjustable cutter holder enables turning and drilling operations to be carried out simultaneously on any Emi-Mec machine.

Drills (over a range of 1 to 16mm in 1mm steps) are held precisely by means of a bi-conical collet.

Simple Cutter Holder

For use with Multi-purpose Single toolholder. Double threads for fixing screws allow reversing and ensure reliable and positive clamping of cutting tools.

| Part No. | Shank Diameter | Shank Length | Tool Size |

| 991641-42 | 20mm | 42mm | 13x11mm |

| 991641-60 | 20mm | 60mm | 13x11mm |

| 991641-80 | 20mm | 80mm | 13x11mm |

Micro-adjustable Toolholder

As per 991641-42 and 991641-60 with the added feature of independent micrometer adjustment.

The vernier ring is divided into 50 divisions whereby 1 div. = 0.02mm in diameter.

| Part No. | Shank Diameter | Shank Length | Tool Size |

| 991701 | 20mm | 42mm | 13x11mm |

| 991702 | 20mm | 60mm | 13x11mm |

Additional Blocks

Part No. 991440

These compact units can be secured onto any or all sides of the Multi-purpose Single Toolholder.

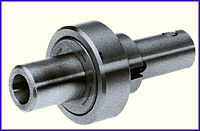

Collet Chuck

Will hold drills up to 16mm diameter with clamping being achieved using bi-conical collets retained in a clamping ring.

| Part No. | Shank Diameter | Body Length |

| 991004 | 1.0" | 45mm |

| 991014 | 1.0" | 70mm |

Bi-conical Collets

Part No. 99ESX25

Consists of a set of 16 collets each of which can cater for a 1mm range of drill size, i.e. 10mm-11mm.

These can be supplied singularly.

Pin Spanner

Part No. 991121

Collet spanner for use with 991004, 991014 and 991404.

Broaching Head

Part No. 99275

This head is designed primarily for producing hexagonal holes. A micro-screw is provided to set the cutting bit on the machine centre-line. The inner shaft is mounted on sealed ball races for precision and long life.

Right hand and left hand rotation is possible to produce a component. The cutting bits can be rapidly replaced and can be supplied in the following sizes.

| Part No: | Size A/F |

| 99283-2 | 2.0mm |

| 99283-3 | 3.0mm |

| 99283-4 | 4.0mm |

| 99283-5 | 5.0mm |

| 99283-6 | 6.0mm |

| 99283-8 | 8.0mm |

| 99283-10 | 10.0mm |

Work Collection Basket Assembly - MicroSprint 26

Part No. MA1-963-01

For mounting on front of bedway casting, under turret slide.

Comprises basket, mounting bolts and fitting instructions. Field fitting requires casting to be drilled and tapped to accept.

Work Collection Basket Assembly - MicroSprint 50

Part No. MS1-963-01

Comprises basket, mounting strip, self tapping screws and fitting instructions.

Please ring 01384-569821 to discuss your tooling requirements.