The MicroSprint 50 - description of features

Machine concept

The MicroSprint 50 is the logical, progressive derivative of the Emi-Mec AutoSprint series of multi-slide, programmable automatic lathes and takes advantage of recent efloatting developments in microprocessor control technology

The MicroSprint 50 has a proven fabricated base developed from the AutoSprint 'S' but reflects improved accuracy and quality assurance standards. It is compatible for use with most existing Series 'S' tooling and equipment.

Control of the four headstock slides, six station turret and all machine functions is by a unique dedicated system, microprocessor based, developed and patented by Emi-Mec. This Computer Enhanced Turning CET control is extremely easy to use and learn. All functions are in plain language, no codes. Its simplicity and logic makes for fast accurate programming.

Only the most applicable facilities of CNC control essential to the specific needs of the MicroSprint 50 are incorporated in the CET control, resulting in a high specification, low cost system.

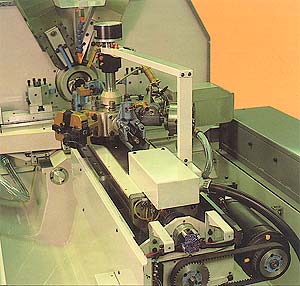

Turret and slide

The six station turret is random index programmable. Indexing is effected by a hydro/pneumatic mechanism integral with the turret saddle.

To minimise turret slide travel the saddle position can be adjusted along the bed-ways.

Slide movement is by a ballscrew, driven by a DC servo motor via a toothed belt. This system produces powerful thrust and its closed loop, feed back monitoring ensures precise programmable positional and feed rate control.

Headstock, spindle and drive

The spindle is mounted in preloaded super precision angular contact sealed bearings at both front and rear. Drive to the spindle is provided by a three speed motor with integral fail safe brake, through a constant mesh two ratio gearbox and poly-vee belt.

30 spindle speeds are available in five ranges; with six speeds in a chosen range programmable for use during automatic cycle. Ranges are selected through easily accessible pick-off gears.

The integral drive motor brake ensures rapid spindle stopping and reversal; assists second operation hand loading and enables cross drill and milling.

Front, rear and overhead slides

Independent induction hardened and ground front and rear slides each have a two position tool post with tool height adjustment. The heavy duty rear slide is adjustable for position on its bed. The front slide can traverse longitudinally.

Progressively fed multi-pass cuts from right to left can be programmed for turning behind a shoulder. Variable traverse strokes may be utilised when using an optional hydraulic copy turning unit.

Twin overhead slides provide for part-off, recessing and chamfering and have longitudinal adjustment.

All headstock slides are capable of independent operation. They are actuated by air intensified hydraulics and traverse in rapid to adjustable pre-set check position and then feed at a steplessly variable controlled rate.

Back feed to front and rear slides is controlled independently by feed rate flow control valves.

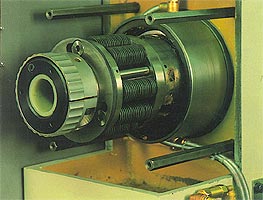

Self compensating collet

The collet operating mechanism is fail safe with spring on, air off control. The spring stack compensation device allows variations in bar stock not exceeding 0.75mm for any one setting.

Lubrication and coolant

An automatic lubrication unit serves 17 points on all slideways, ballscrew and indexing mechanism.

Coolant is programmable to the main supply distributor and turret nozzles.

Automatic bar feed

An automatic electric bar feed, 4 metre length capacity, capable of accommodating bar diameters from 10 to 50mm is provided. It is arranged to be swung forward at the machine end to load a new bar.

It is fitted with an end of bar switch to shut the machine down and operate a warning light at the completion of the automatic cycle.

Safety

The MicroSprint 50 incorporates a range of safeguards:

- emergency stop button which stops spindle, applies brake and homes program.

- turret interlock ensures turret is fully indexed before forward travel can commence.

- control lock-out key switch to prevent tampering with program.

- thermistor protection of main motor.

- collet/chuck control buttons linked to spindle brake circuit for operator protection.

- 12V brilliant Halogen work area light.

- sliding work area guard with electro mechanical interlock.

- dual interconnected start buttons ensure hands clear tooling area before starting in auto-cycle.