The MicroSprint 50 - Options

Magazine loading

Where unmanned second operation machining is required on blanks; castings; previously turned parts; extrusions etc., magazine loading equipment can be supplied. Three types are available; rear end through spindle (for long shafts); cross slide and rear of turret.

Magazine loading applications will be quoted against full supporting information.

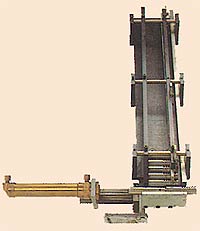

Automatic magazine bar feeders

The use of an automatic bar feeder greatly improves the overall efficiency of an automatic lathe as it removes dependence on operator availability when a new bar needs to be loaded.

Where long parts combine with short machining times and/or several machines are tended by a single operator, they become essential and extremely cost effective.

Stationary drilling and milling

A range of air driven attachments are available capable of performing a variety of drilling or milling operations on a component held stationary in the spindle.

Air chucking

A range of chucks and fixtures are available to suit the specific requirements of second operation machining on components which cannot be held in a collet.

Copy turning

A copy turning attachment is available for fitment on the front traversing slide.

The CET control has the facility to program multi pass, progressive feed and variable stroke traverse to fully complement this attachment.