The MicroSprint 50 - Specification

Work capacity

Max Diameter Bar | 50.8mm |

Max Diameter in 200mm Chuck | 160mm grip |

Max Die Head Size | 1.25in. |

Headstock

Spindle | Hardened and Ground |

Hole through spindle | 51.6mm |

Spindle bearings, front and rear | Matched pair of angular contact (EP5) |

Spindle bearing diameter, front | 90mm |

Spindle nose | A2.6 to BS 4442 fitted with sleeve and nosecap to accept V-120 series multibore collets |

Spindle drive

Type | Poly-vee be drive from 3 speed motor through constant mesh oil immersed 2 ratio gearbox with pick off gears to give 5 ranges |

Spindle speeds RPM | range 1 | 50 | 65 | 100 | 315 | 420 | 630 |

range 2 | 65 | 90 | 135 | 420 | 565 | 840 | |

range 3 | 100 | 135 | 200 | 640 | 850 | 1275 | |

range 4 | 150 | 205 | 300 | 965 | 1295 | 1930 | |

range 5 | 205 | 275 | 415 | 1300 | 1740 | 2600 rpm |

AC motor power | 5.5/5.5/3.75 kW (7.5/7.5/5 HP) |

AC motor type | T.E.F.C. 3 speed reversible with integral fail safe brake |

Power supply

Electrical rating | 415/440 volts, 3 phase, 50 hertz or as appropriate to local supply. |

Power requirement | 16.5 amps constant, 79 amps surge. Supply rating 63 amps fused, 10sq.mm cable |

Turret

Number of faces | 6, random index, unidirectional |

Indexing time (max) | 1 sec, stn to stn; 2.5 secs, stn 1 to 5 |

Dia of tool holes | 25.4mm (Optional 38.1 mm) |

Centre of holes to top of slide | 69mm |

Turret slide

Max effective working stroke | 200mm |

Max movement | 400mm |

Feedrate range, stepless | 0-2000mm/min. |

Number of feeds | Infinite, forward or back. |

Rapid traverse rate | 8000mm/min. |

Drive | Recirculating ball screw driven by DC servo motor via toothed belt. |

Max thrust | 13000 Newtons (2830 lbf.) |

Cross slides

Type | High thrust independent, two. |

Slide drives | Hydraulic/pneumatic cylinder |

Max thrust | 7500 Newtons (1700 lbf.) |

Tool size | 19mm x 25.4mm |

Max distance between posts | 432mm |

Back feeding | Programmable on both slides |

Front: | 2 Axis traversing, programmable to accept optional copying unit |

Slide stroke to centre line | 114mm |

Feedrate range, stepless | 0-2000mm/min. |

Longitudinal travel | 152mm. right to left |

Longitudinal feedrate range | 0-2000mm/min. |

Rapid traverse rate | 6000mm/min. |

Rear: | Single Axis, fixed adjustable |

Slide stroke to centreline | 114mm. |

Feedrate range, stepless | 0-2000mm/min. |

Rapid traverse rate | 6000mm/min |

Twin overhead slides

Type | Twin 65° recess/part off units |

Slide drives | Hydraulic/pneumatic cylinders |

Max thrust | 2700 Newtons (6001bf.) |

Tool size | 16mm x 16mm |

Stroke | 89mm |

Tool post to centreline, max. | 114mm |

Longitudinal adjustment101mm | Feedrate range, stepless |

0-1000mm/min. | Rapid traverse rate |

2000mm/min. |

Lubrication

Spindle | Greased for life with Kluber Isoflex. |

Slideways, indexing bolt and turret | 12 point automatic lubrication, capacity 0.5 litres Mobil vactra 2 oil or equiv. |

Coolant system

Standard | Centrifugal pump. |

Application | Overhead supply and turret nozzles (selected on control panel) |

Flowrate | 25 litres per min. |

Reservoir capacity | 80 litres working, 120 litres max. |

(Heavy coolant oils above ISO 20 may need a more powerful pump). |

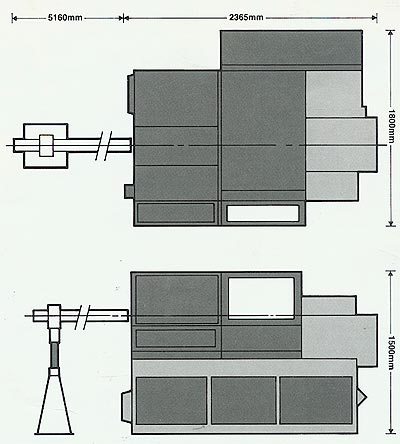

Dimensions

Weight | 2700kg (less barfeed) |

Barfeed

Type | Emi-Mec electric motor driven |

Bar capacity | 10 to 50mm. dia x 4 metres long. |

Air

Supply | 80 p.s.i. (5.62 Kg/cm.sq.) |

Consumption typically | 4 cub.ft/min (0.12 cub. m/min) |

Control

Type | Computer Enhanced Turning CET special purpose system, based on the INTEL APX 188, 16 bit microprocessor with Mylar panel featuring touch sensitive keys and vertical line cursor function programming. |

Manual controls | Manual control of all slides, spindle, coolant and turret from control panel. |

Data input | a) Manual by means of function prompt and numeric keys. Function LED's give visibility of the line being programmed plus two lines before and two lines after. |

Functions controlled | Turret slide; feed rate, check and stop positioning. Index station position. |

Turret canned cycles | Feed forward (rapid, feed and rapid out); feed return; rapid return; woodpecker drill; feed bar to stop; tapping and multipass function to front slide. |

Addition features | Quantity counter, diagnostic display. |

Safety

Safety guard Spindle brake | Partially enclosed, with electro-mechanical interlock. Brake integral with spindle motor stops within 2 secs from 2600 rpm. |

Machines incorporate safety and design features, salary devices, guarding arrangements and are supplied with such information as to their safe operation and use, that we believe, so far as it is reasonably practical, they are safe and in compliance with the legal requirements of the Health and Safety at Work etc. Act 1974.