The DrillSprint 500 - description of features

Table

A robust tee slotted traversing (two axes) work table, programmable for simple or complex patterns, brings component(s) to the required position under the rotating tool spindle.

The table is mounted on linear recirculating ball bushings and traversed in the X and Y axes by two DC servo motor driven precision ballscrews.

Turret

The six spindle rapid indexing turret is mounted on a DC servo/ ballscrew driven slide (Z axis) in a saddle, fixed adjustable, on the two vertical support columns. This enables correct turret slide to component height relationship, minimising tool travel and slide wear.

The turret provides 12 speed options (six within a program) to the tool spindles. And is programmable for speed, feed, dwell, travel and index.

Lubrication

Automatic centralised lubrication is provided to slides and ballscrews for extended maintenance free operation.

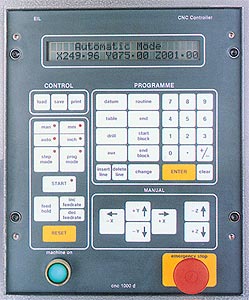

Control

The EIL model 1000 CNC control is programmed in plain language through the oil impervious, Mylar touch sensitive membrane key panel. The high clarity LCD display prompts answers in required sequence and format. There are no codes to learn; reducing training time and speeding machine into fully effective production.

An optional plug in 64K cartridge memory extension unit having the capability to store approximately 60 programmes is available. This is necessary if repeat reprogramming for each different application is to be avoided.

Safety

Machines incorporate safety and design features, safety devices, guarding arrangements and are supplied with such information as to their safe operation and use, that we believe, so far as is reasonably practical, they are safe and are in compliance with the legal requirements of the Health and Safety at Work etc Act 1974.