The AutoSprint S - description of features

Transmission

The power drive to the spindle is transmitted from the three-speed 71 h.p. motor via a constant mesh oil-immersed two ratio gear box through five vee belts. Thirty spindle speeds are available in five ranges of six speeds. Any chosen range can be programmed in an automatic cycle, the remaining four ranges are attained by the changing of easily accessible pick-off gears. The selection of spindle speeds from 1 to 6 automatically engages the correct combination of clutch and motor speed. The spindle is mounted in pre-loaded double angular contact bearings at the front and is supported by a large single roller bearing at the rear. Spindle speeds range from 50-2560 rpm.

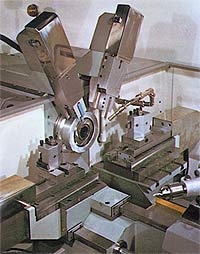

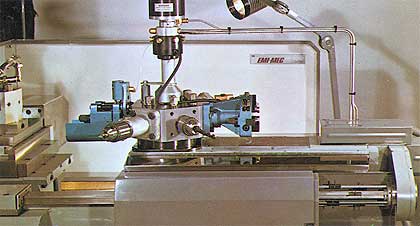

All slides independent - longitudinal traversing front slide and twin overhead slides

Real versatility is built into the Autosprint 'S' with split cross slides and dual 65° overhead slides, all capable of independent operation. The cross slides are of massive construction and are designed for heavy work. The front cross slide, mounted on a double rail for maximum rigidity, traverses longitudinally enabling, for example, long diameters to be turned behind a shoulder without using form tools.

With the optional multi-pass printed circuit board, the front slide is able to take progressive cuts from right to left until the material is reduced to the correct diameter. In this way a fully automatic 'centre lathe' type operation using normal turning tools is possible, making the machine ideal for very short runs and the six inches of longitudinal traverse also enables an optional copy turning unit to be fitted.

Twin overhead slides provide for part-off, recessing and chamfering and have longitudinal adjustment of up to 100 mm (4"). These are essential, greatly helping to minimise the need for complicated combined tooling and further reducing the machine set up time.

Self compensating collet

This unique feature of the AutoSprint 'S' allows for variation in bar size of up to 0.75mm (0.030 in.) once the collet has been primarily adjusted.

Significant operating economy is provided by eliminating the need for frequent collet adjustment and the setter is able to operate with much wider tolerances in bar size.

This original design, uses a series of banked springs operating through mechanical advantages and controlled by static hydraulics giving a theoretical thrust of 10,000 lb. (4536 Kgs) to a multibore collet.

Electronic check sensors

In place of waterproof switches, which experience has shown to be susceptible to troubles, all the rapid check settings on the machine are activated by electronic sensors which have no contact between the moving dolly and the 'switch'. This also enables the settings to be made manually by novel sliding rack trips obviating the use of keys or spanners, further reducing machine set-up time.

Auto-selecting turret

Any one of the six stations of the turret can be directly selected in any sequence without indexing the turret sequentially to the required position. This auto-selecting capability, which allows substantial time saving and great flexibility in tool setting, is a considerable advance over conventional skip indexing, and is of particular benefit when copying.

In addition, the auto-selecting turret enables movement of the turret to be interlocked with the turret station selector so that the turret will not proceed until the correct station has been located. Each turret station has its own feed control needle valve which is automatically selected. The usual EMI-MEC features such as woodpecker feed are also included.

Air economy system

The slides for this 50mm machine require high pressures, particularly since the complications of a mechanical drive to the turret have been abandoned. Operation with air pressures alone would require very large power units and very great air consumption. To overcome this problem EMI-MEC has designed a unique new system to give high economy of air and still maintain the necessary high thrust to the slides. This is achieved by advancing the slide to its rapid check position with a smaller air cylinder at which point the pneumatic/hydraulic intensifier takes over and supplies a high pressure for the working stroke. This unique design avoids the necessity for the sophisticated circuitry which would otherwise be required in hydraulic machines. Typical air consumption for a theoretical programme using all slides on an average workpiece would be 5� cu.ft. (0.150m3) per minute giving a theoretical thrust of 1700 lb. (7.70 Kgs.) for the cross slides and 2,830 lb. (1,300 Kgs.) for the turret.

Automatic bar feed

The bar feed to the machine is electrically driven forward and in reverse through a slipping clutch. An end of bar switch stops the machine at the end of the automatic cycle and operates a pedestal mounted amber flashing light.

Noise and environmental control

The air system incorporates a number of silencers and filters which drastically reduce the noise level normally associated with such machines and prevents oil mist venting to the atmosphere. The bar feed tube is also silenced.

Rapid spindle braking

A feature of the AutoSprint 'S' is the electrical and mechanical braking arrangement which provides very rapid stopping of the spindle from even the highest speed - invaluable for hand loading chuck work. The dual circuit brake can be programmed to remain engaged for operations such as cross hole drilling.